Nplooj springs yog ib feem tseem ceeb ntawm lub tsheb ncua kev kawm ntawv, muab kev txhawb nqa thiab ruaj khov.Txhawm rau tiv thaiv qhov kev ntxhov siab tas li thiab siab lawv ua siab ntev, cov nplooj hlav yuav tsum tau ua kom tawv thiab tempered kom ntseeg tau tias lawv cov kav ntev thiab kav ntev.Hardening thiab tempering yog ob txheej txheem tseem ceeb uas siv los ntxiv dag zog rau cov khoom siv thiab txhim kho nws cov khoom siv kho tshuab.Hauv tsab xov xwm no, peb yuav tshawb txog cov txheej txheem ntawm quenching, tempering, thiab lawv daim ntawv thov nyob rau hauv hardening thiab tempering ntawm nplooj springs.

Quenchingyog ib txheej txheem uas muaj cua sov cov khoom mus rau qhov kub thiab txias sai sai hauv cov kua nruab nrab, xws li dej los yog roj.Qhov txias txias no ua rau cov khoom ua kom tawv, ua rau nws lub zog thiab toughness.Thaum nws los txog rau nplooj springs,quenchingfeem ntau yog siv los ua kom lub zog ntawm cov hlau, ua rau nws tiv taus hnav thiab qaug zog.Cov txheej txheem quenching tshwj xeeb siv rau cov nplooj springs nyob ntawm qhov muaj pes tsawg leeg ntawm cov hlau thiab cov khoom siv kho tshuab uas xav tau.

Tom qab cov txheej txheem quenching, cov khoom yuav nyuaj heev thiab nkig.Txhawm rau txo qhov brittleness thiab txhim kho cov ntaub ntawv toughness, tempering yog nqa tawm.Tempering yuav tsum rov ua kom cov khoom quenched kom qis dua thiab tom qab ntawd txias nws ntawm tus nqi qis dua.Cov txheej txheem no tso cai rau cov kev ntxhov siab sab hauv hauv cov khoom kom tau txais kev nplij siab, ua rau muaj cov khoom siv ntau dua thiab tsis muaj nkig.Tempering kuj pab txhim kho cov khoom tiv thaiv kev cuam tshuam thiab kev poob siab.

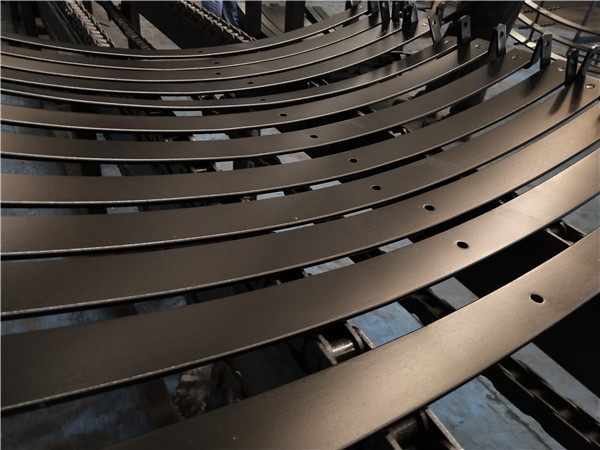

Cov txheej txheem hardening thiab tempering rau nplooj springs pib nrog kev xaiv ntawm cov hlau alloy uas tsim nyog.Feem ntau siv hlau alloys rau nplooj springs muaj xws li 5160, 9260, thiab 1095. Cov alloys no raug xaiv rau lawv lub zog tensile siab, qaug zog tsis kam, thiab muaj peev xwm tiv taus hnyav.Thaum cov hlau raug xaiv, nws yog rhuab mus rau ib tug tshwj xeeb kub raws li cov alloy muaj pes tsawg leeg thiab ces quenched nyob rau hauv ib tug tsim nyog nruab nrab kom ua tau raws li qhov xav tau hardness.

Tom qab quenching, cov khoom yog ces tempered mus rau qhov yuav tsum tau muaj zog thiab toughness.Lub tempering kub thiab lub sij hawm yog ua tib zoo tswj kom ua tau raws li qhov xav tau ntawm txhua yam khoom, xws li hardness, lub zog, thiab ductility.Qhov kawg tshwm sim yog nplooj ntoos hlav uas muaj zog, yoog raws, thiab muaj peev xwm tiv taus qhov hnyav ntawm cov ntawv thov hnyav.

Hardening thiab temperingntawm nplooj springs yog ib qho tseem ceeb txheej txheem uas yuav tsum tau precision thiab kev txawj ntse.Kev tsis zoo quenching thiab tempering tuaj yeem ua rau ntau yam teeb meem, xws li tawg, warping, lossis tsis txaus hardness.Yog li ntawd, nws yog ib qho tseem ceeb uas yuav tsum ua raws li kev lag luam kev coj ua zoo tshaj plaws thiab ua raws li kev tswj hwm nruj kom paub meej tias cov nplooj springs ua tau raws li qhov tsim nyog.

Hauv kev xaus, lub hardening thiabtempering ntawm nplooj springsua lub luag haujlwm tseem ceeb hauv kev ua kom lawv cov kev ua tau zoo thiab kev ua haujlwm ntev.Kev sib xyaw ua ke ntawm cov txheej txheem quenching thiab tempering ua rau cov khoom siv uas yog ob qho tib si nyuaj thiab tawv, ua rau nws zoo rau cov kev xav tau uas cov nplooj hlav tau raug.Los ntawm kev nkag siab txog cov txheej txheem ntawm quenching thiab tempering thiab lawv daim ntawv thov nyob rau hauv hardening thiab tempering ntawm nplooj springs, manufacturers muaj peev xwm tsim high-zoo, txhim khu kev qha nplooj springs uas ua tau raws li cov kev xav tau ntawm ntau yam automotive thiab industrial daim ntaub ntawv.

Post lub sij hawm: Dec-11-2023